Delivery to the Baltics - 1-2, Europe - 5-7, other countries - 7-21 days unless otherwise indicated in the card of the ordered product.

Price:

For recuperation system installation, write to us at [email protected] or call our partner who performs the installation work +37069809112, Darius.

Heat recovery ventilation system. What is it and how to choose the right one?

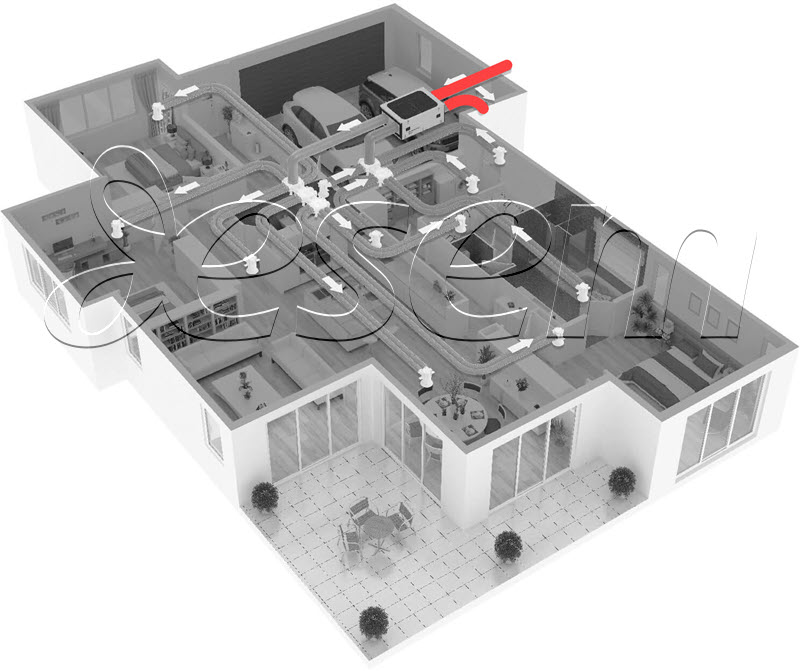

A heat recovery system is a ventilation system that changes the air in a premises by recovering the heat energy of the exhaust air. The heat energy is recovered by a heat exchanger in the recuperator, which efficiently absorbs the energy of the extracted warm and used air and transfers it to the incoming fresh air from outside. A heat recovery unit is usually equipped with two fans, one supplying air to the room and the other extracting air from the room through ducts in the room. The air is transported through a heat exchanger which recovers or returns the heat of the extracted air to the drawn air. Such a system is called a heat recovery system or heat recovery. Depending on the efficiency of the recuperator, an average of ~90% of the heat energy is saved. This results in fresh air being supplied to the rooms, a comfortable environment and significant savings in potential heating costs.

Why do I need a heat recovery system?

The key benefits of a heat recovery system:

fresh air indoors

the air supplied to the room is passed through filters that clean dust, pollen and particulates (depending on the filter class chosen)

significant cost savings through heat recovering

the change in indoor air will protect the walls against mould, excess moisture and window dew

correctly adjusted airflows will help to prevent the spread of odours in the room (e.g. air from the kitchen or toilet will not get into other rooms)

How do I choose the right heat recovery system?

When choosing a heat recovery system for a residential building - a house, an apartment, or a public space - a hairdresser's salon, an office, a café, a restaurant or a workshop, here are the important things to consider:

calculate the cubic capacity of the premises (if the square footage of the premises is 100 m² and the ceiling height is 2.5 m, then the cubic capacity of your premises will be 100 x 2.5 = 250 m³)

consider the purpose of the space and calculate the air change rate for each room, and consider the capacity of the unit you will need. Our recommended air change frequency table will help you to do this (of course, the air change frequency also depends on the number of people in the room):

|

Building |

Premises |

Air change x 1 hour |

m³/h for 1 person |

|

Residential house, apartment, cottage |

Bedroom |

1-4 |

18-40 |

|

|

Living room |

1-4 |

18-40 |

|

|

Common areas |

0.5-2 |

18-25 |

|

|

WC, shower room |

6-10 |

40-60 |

|

|

Kitchen |

6-10 |

40-60 |

|

Hotels |

Reception |

1-4 |

18-40 |

|

|

Waiting room |

1-4 |

18-40 |

|

|

WC, shower |

6-10 |

40-60 |

|

|

Kitchen |

6-10 |

40-60 |

|

|

Catering rooms |

6-10 |

40-60 |

|

Offices, hospitals, nursing homes, conference rooms, cinemas, theatres |

All premises |

8-12 |

40-60 |

|

Bars, restaurants |

All premises |

6-12 |

40-60 |

|

|

Kitchens |

12-30 |

|

|

Sport halls |

|

12-20 |

|

|

Educational institutions |

|

1-4 |

18-40 |

|

Hairdressing salons, cosmetic salons |

|

4-6 |

40-50 |

|

Shops, supermarkets |

|

1-4 |

18-40 |

As a rough estimate, if a family of 4 people lives in a 100 m² house or cottage with a cubic capacity of 250 m³, a 250-300 m³/h recuperator or heat recovery unit should be chosen. After all, a lot of space is consumed by household appliances and furniture, so the actual cubic capacity of the rooms will be smaller than we calculate. However, it is very important that the recuperator chosen has a capacity reserve, i.e. it does not always run at maximum speed. We are also not driving the car at maximum speed. You may need to run at maximum speed when you have many guests.

So here we go:

find the room where you plan to install the recuperator, in that room assess where you will install the heat recovery unit (ceiling-mounted, wall-mounted or ground-mounted)

according to the chosen room and the type of recuperator installation, determine the points on the outside wall where the air outlet and inlet openings will have to be installed (the air outlet and inlet openings must be at least as small as the recuperator's outlet and inlet openings, we recommend installing a larger one, for example if the recuperator's openings are 160 mm, then install outdoor openings and grilles at 200 mm, so that the system will have minimum resistance and pressure loss)

draw up a plan for the ductwork from the outside wall to the recuperator and from the recuperator to the indoor end points

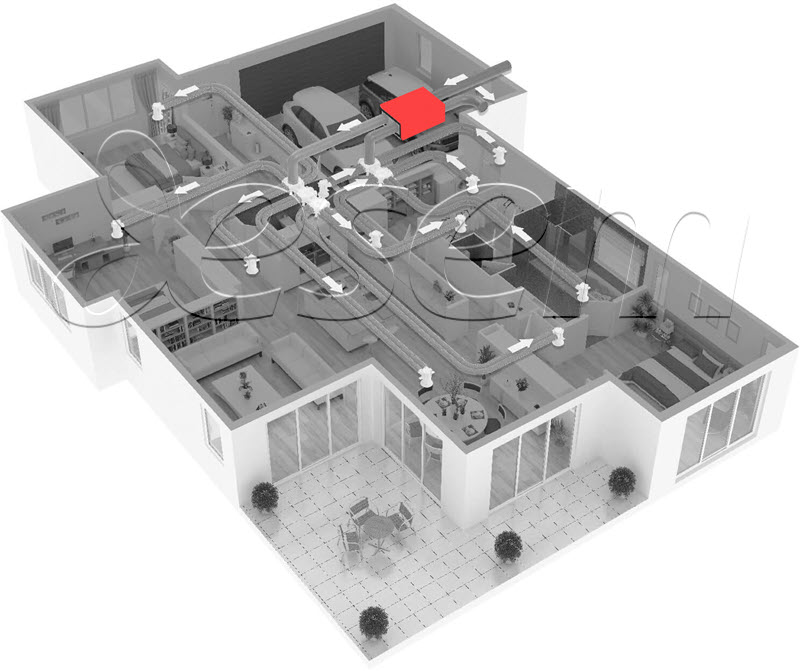

To make it easier and simpler for you to draw up a plan for the heat recovery system, we have decided to divide it into three parts (each part will be described in detail, in sequential order of which equipment is recommended to be installed where):

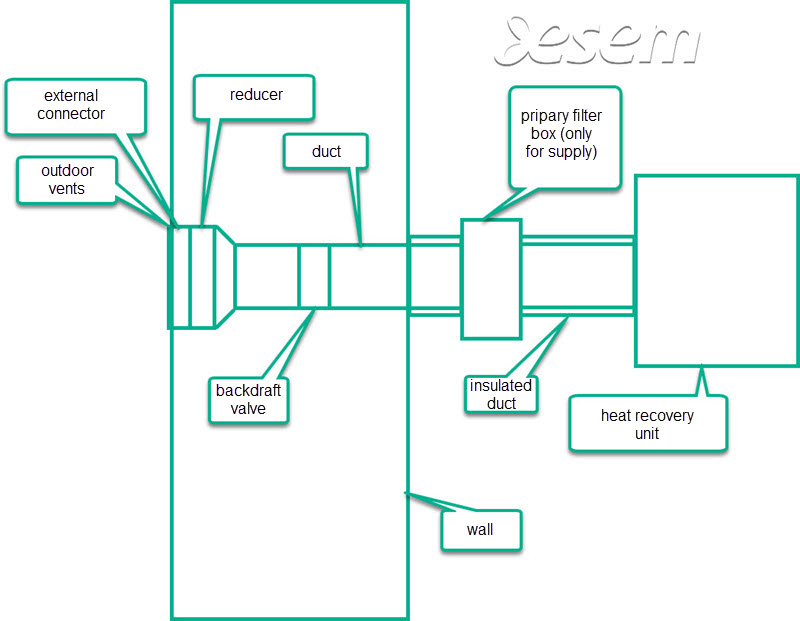

from the outdoor vent grille to the recuperator:

The exhaust and supply air grilles are installed on the outside wall, connected to the supply duct via an external connector and reducer, a non-return valve is installed in the duct (to prevent cold, insects and dust from entering the system when the recuperator is switched off), and the supply duct is connected to the air filter box right next to the wall (a primary EU3 filter is installed in the air filter box to protect your system against dust, The air filter box is already connected on both sides by an insulated duct that goes all the way to the recuperator (the insulated duct will prevent condensation on the outside of the duct and act as a noise attenuator) and the air filter box is not needed on the exhaust duct (not necessary, but better insulated). Noise attenuators can still be installed upstream of the recuperator but are not necessary.

A heat recovery ventilator is installed at the selected location, to which supply and extract air ducts from indoors and outdoors are connected. We recommend installing the unit in a heated room (if you install it in an unheated room, we recommend that you make an additional insulated box or casing for it). If you are going to hang the unit on the ceiling, use special shock absorbers to prevent possible vibration in the system. It is possible to choose between an air-conditioned recuperator and a heater - the unit will have an additional air-conditioning function in summer and a heating function in winter. Please contact us directly for this option.

from the heat recovery unit to the supply and extract air points in the rooms

Noise attenuators are connected from the heat recovery unit to the indoor side, and the main supply and extract air ducts are connected immediately from the recuperator. Two duct systems are available - spiral ducting system or HDPE antibacterial, antistatic rigid duct system. Which system is better? This can be answered by feedback from installers in the public websites or by our advice and rating below.

It is a very simple duct system with main ducts for extraction and supply and branches to the rooms. At the ends of the branches, dampers are installed to regulate the air flow, and diffusers are installed behind the dampers. The installation of flow control dampers is necessary for the proper flow control in all rooms. Failure not to install them at the closer points may result in whistling and extraneous noises due to high flow.

Advantages of the system: low cost, very good airflows, easy installation

Disadvantages: Requires considerable space under the ceiling, requires a large number of connecting components - elbows, tees, saddles, couplings, etc.

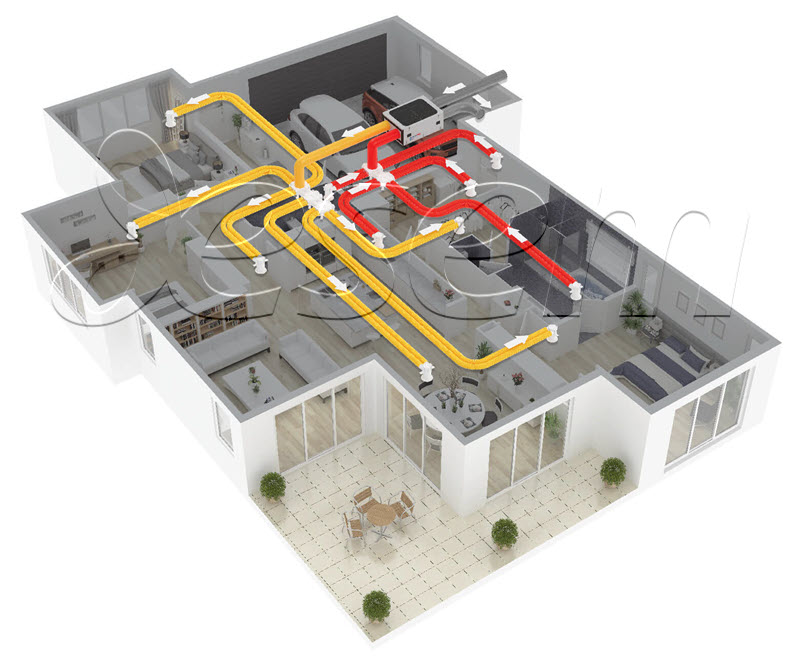

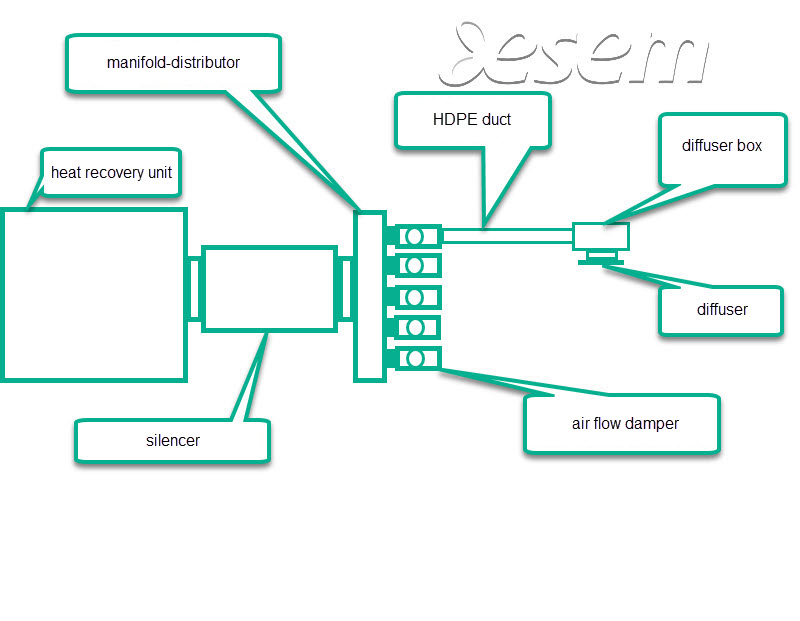

It is a duct system where main duct manifold-distributors are used for air extraction and supply. The connection of the recuperator to the main distributors is via silencers. Rigid and flexible Ø63 mm, Ø75 mm, Ø90 mm or 132x52 mm HDPE ducts shall be routed from the main distributors to the rooms for supply and extract air. The HDPE ducts shall be connected to the main manifold-distributors via airflow control dampers. These dampers are necessary to regulate the air flows in the rooms, by reducing the flow for closer rooms and increasing the flow for more distant rooms. Diffuser boxes shall be connected at the ends of the ducts leading to the rooms.

We recommend that the supply diffuser boxes are located at the window area and the extract diffuser boxes at the door. In a kitchen or living room, the supply diffusers shall be located at the seating area, at the dining table, and the extract diffusers closer to the kitchen worktops. In WCs and showers, only extraction diffusers shall be installed. This will prevent odours from spreading to other rooms. Throughout the system, the airflows are adjusted so that there are ~15-30% more supply air points than extract air points. This will create an overpressure in the room, which will control the spread of odours in the room.

Advantages of the system: anti-static, anti-bacterial, mould-resistant ducts, easy duct routing, anti-bacterial manifold-distributors and diffuser boxes, low ceiling or wall space requirements, not much connecting components, easy installation

Disadvantages of the system: higher cost than spiral duct system

This figure shows an example of an HDPE flexible duct system:

Riga, Tallin, Helsinki or Oslo? Maybe Norway or the UK? It doesn't matter where you live - we offer telephone advice to all, and we deliver equipment to your door very quickly, as we keep around 95% of our range in stock and import almost everything ourselves. That's why we can offer good prices and fast delivery.

Another system is the decentralised recuperation system.

This system is based on mini heat recovery units which are installed in every room of the building. More details in the category of mini recuperators.