- TA HP - ducted axial fans with aerodynamic impeller blades and adjustable pitch angle for maximum efficiency. They are particularly suitable for applications where pressure and air volume are required to fully meet high specifications

- improved aerodynamic wing blade design and efficient air circulation, lower noise levels and long-term economic advantages make them particularly suitable for applications requiring high performance and lower energy consumption

- units are made to your specifications - if you are interested in these models, please send us your requirements for an estimate

- TA-HP are durable, robust and highly efficient thanks to the aerodynamic blades optimised by CFD design. In addition, they are easy to install due to their long body design

- available in a wide range of models from 400 to 1600 mm Ø, with 2, 4, 6, 8 pole motors, 6, 9 and 12 blade versions

- higher pressures can be achieved by using two fans in series

- fan performance and sound emission in accordance with Amca 210 and 301, category D

- for each fan diameter, a wide range of pitch angles can be set during installation due to the hub design, allowing the exact optimum operating point to be achieved for each ventilation project

- the motors in this series are suitable for operation in a temperature range from -20 °C to + 70 °C

- ErP compliance is determined at the screening stage using Blowdyn 2.0 screening software or by contacting us

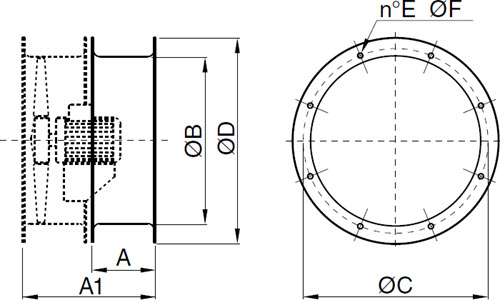

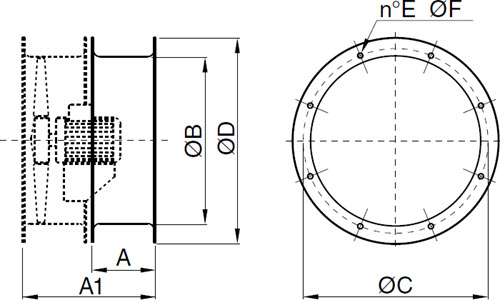

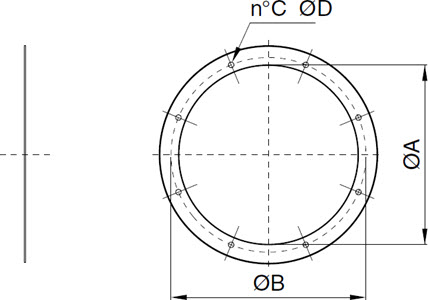

- long housing made of epoxy-painted steel sheet with mounting flanges manufactured according to UNI ISO 6580-EUROVENT standard

- high performance axial impeller with aerodynamic blades, all in die-cast aluminium. Balanced in accordance with ISO 1940. Variable angle of bank in stationary position

- housing equipped with a maintenance door

ENGINE

- asynchronous three-phase IE3 motors in accordance with international standards IEC 60034, IEC 60072, EMC 2014/30/EU, LVD 2014/35/EU, CE marked, IP 55, class F

- suitable for S1 operation under constant load

- air flow from impeller to motor

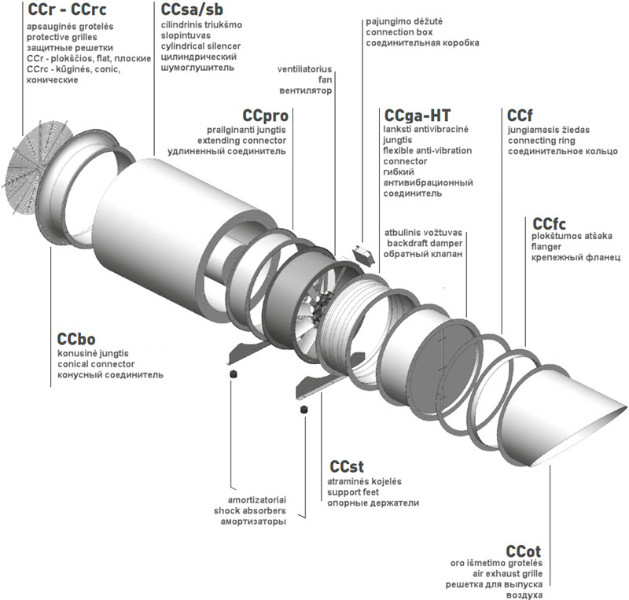

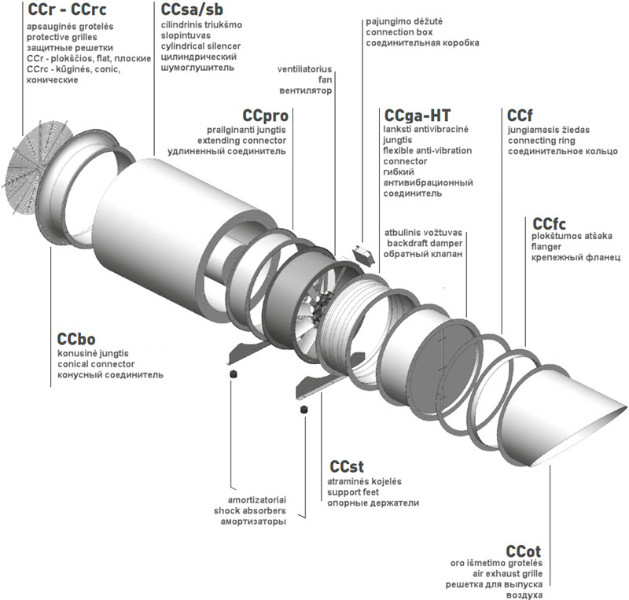

Recommended installation scheme for TA HP fans:

ACCESSORIES

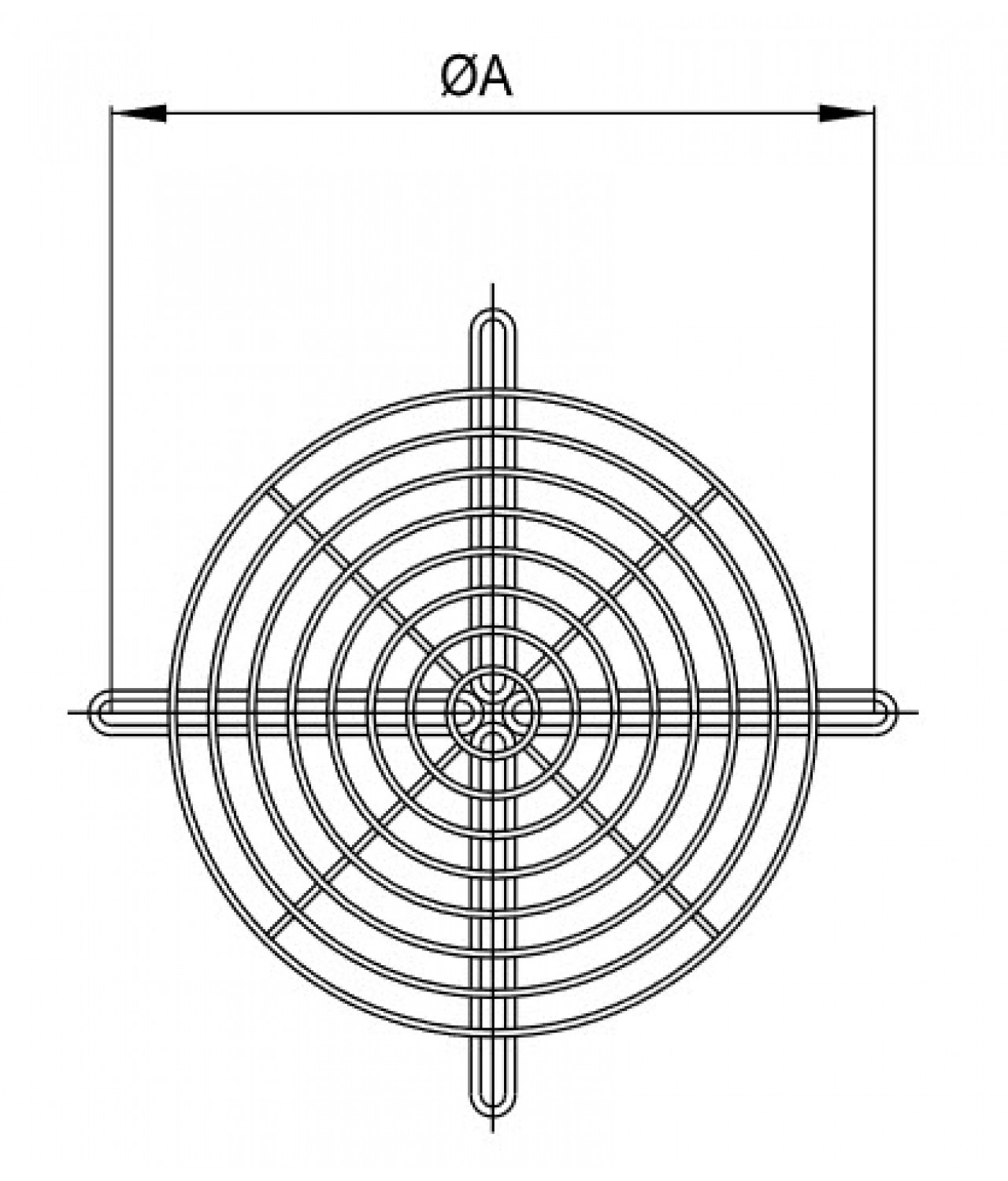

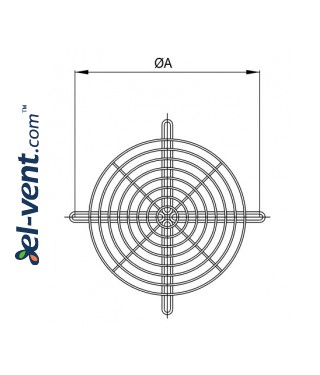

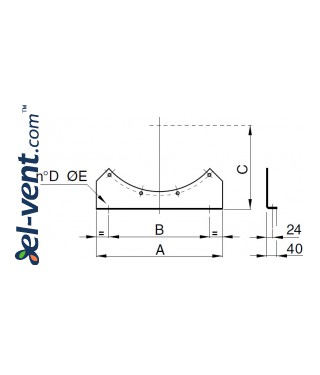

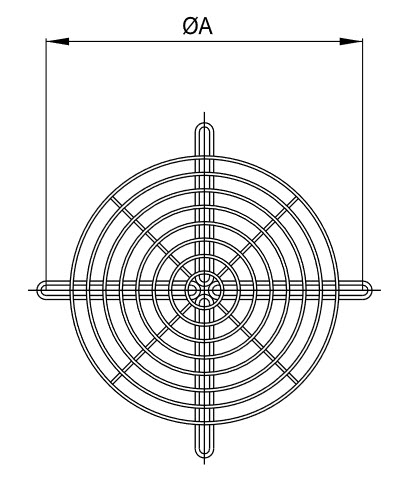

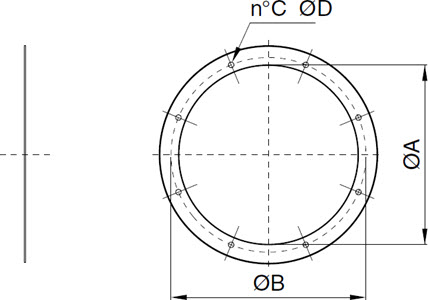

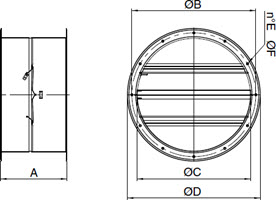

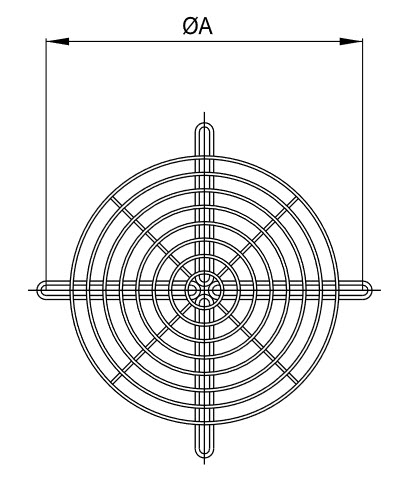

- CCr protective grille - only for AC-B models, complies with UNI 12499

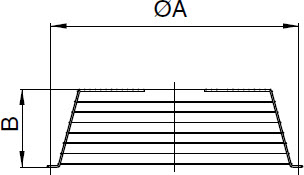

- CCrc - conical grille (the narrower part is mounted on the motor)

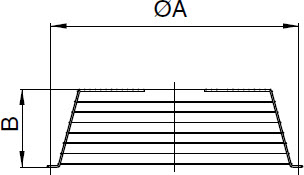

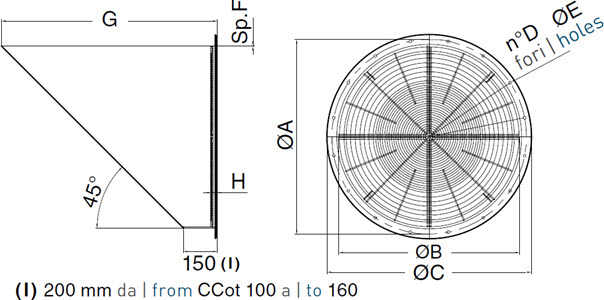

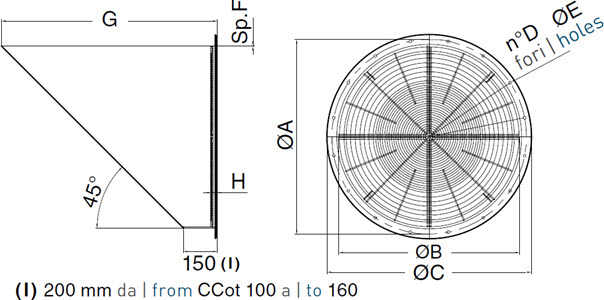

- CCbo - conical air inlet or outlet which results in higher fan efficiency. Manufactured from steel sheet in accordance with UNI ISO6580 - EUROVENT and coated with a weatherproof epoxy coating. The grommet shall be attached to the CC fan and the CCr grille shall be attached to the outside of the CC fan, for example CCbo + CCr80

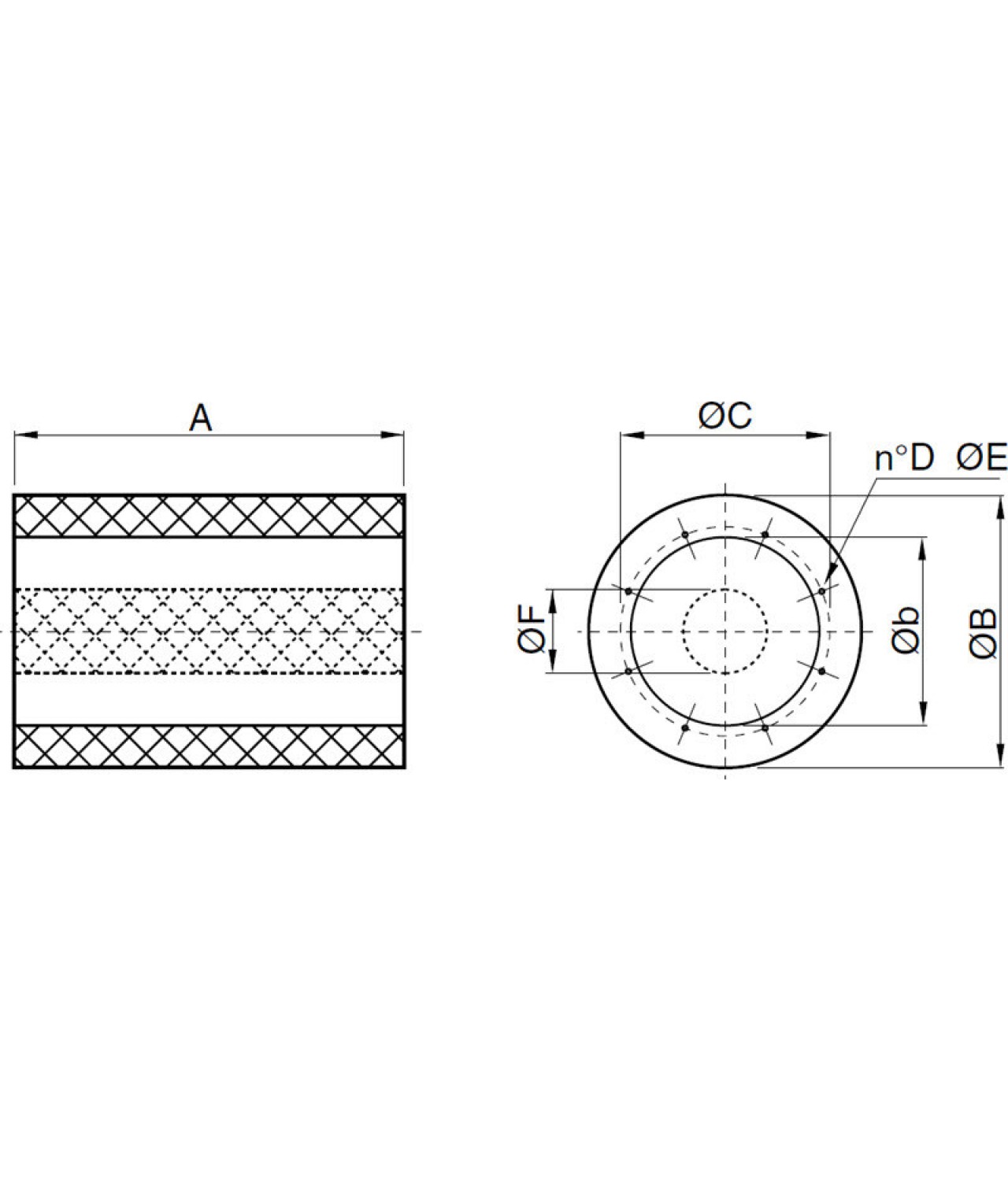

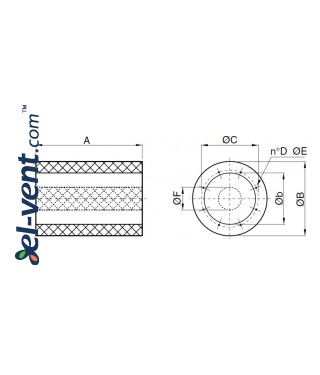

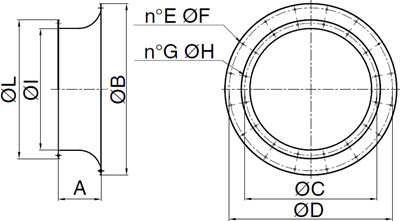

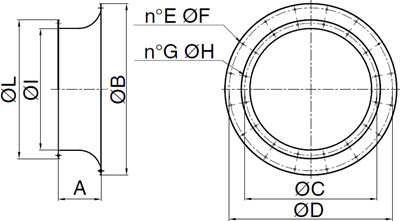

- CCs cylindrical silencers - available in two versions: without a capsule (CCsa) and with a capsule (CCsb) in the centre of the silencer. With a capsule, the noise reduction is greater, but there is additional pressure loss in the system. Both versions can be attached to the corresponding CC flange at the inlet and outlet. The CCsa series does not create additional pressure losses. The CCsb series creates additional pressure losses as shown in the pressure loss graphs on the catalogue page. The dampers are made of galvanised steel. The inner part and the capsule are made of perforated sheet for effective sound absorption by the acoustic mineral wool lining. The operating temperature range is from -40 °C to +150 °C. Suggested damper lengths 1 x damper diameter x1D, 1.5 x damper diameter x1.5D, 2.0 x damper diameter x2.0D, i.e. if the diameter of the silencer is 400 mm and the silencer diameter is 1.5D, then the length of the silencer will be 600 mm

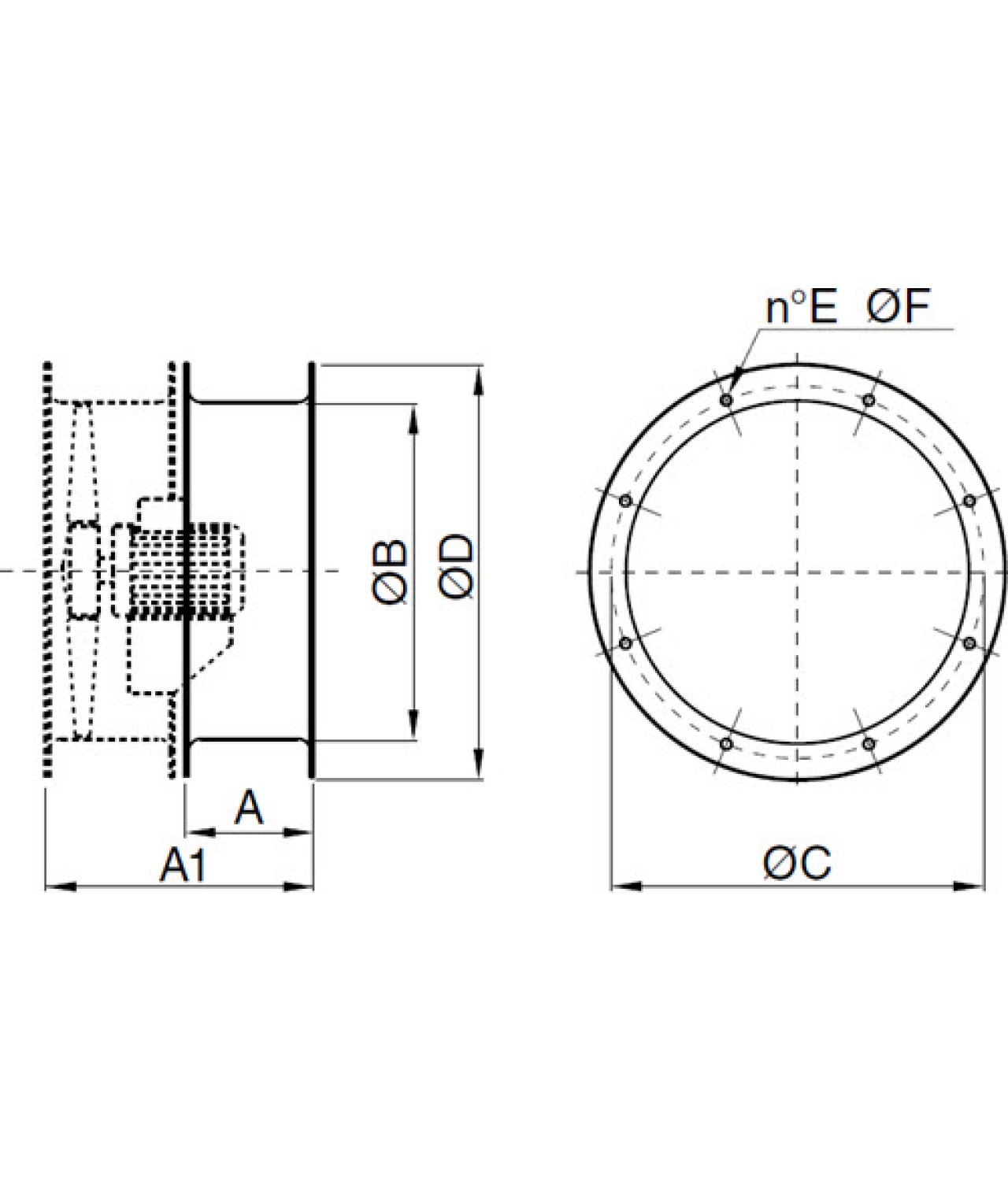

- CCpro - an extension connector that converts the standard short body version of the fan into a long body version - the impeller and motor remain fully protected inside the body. Manufactured from steel sheet in accordance with UNI ISO6580 - EUROVENT and coated with a weatherproof epoxy coating. Supplied with inspection holes and holes for the cable.

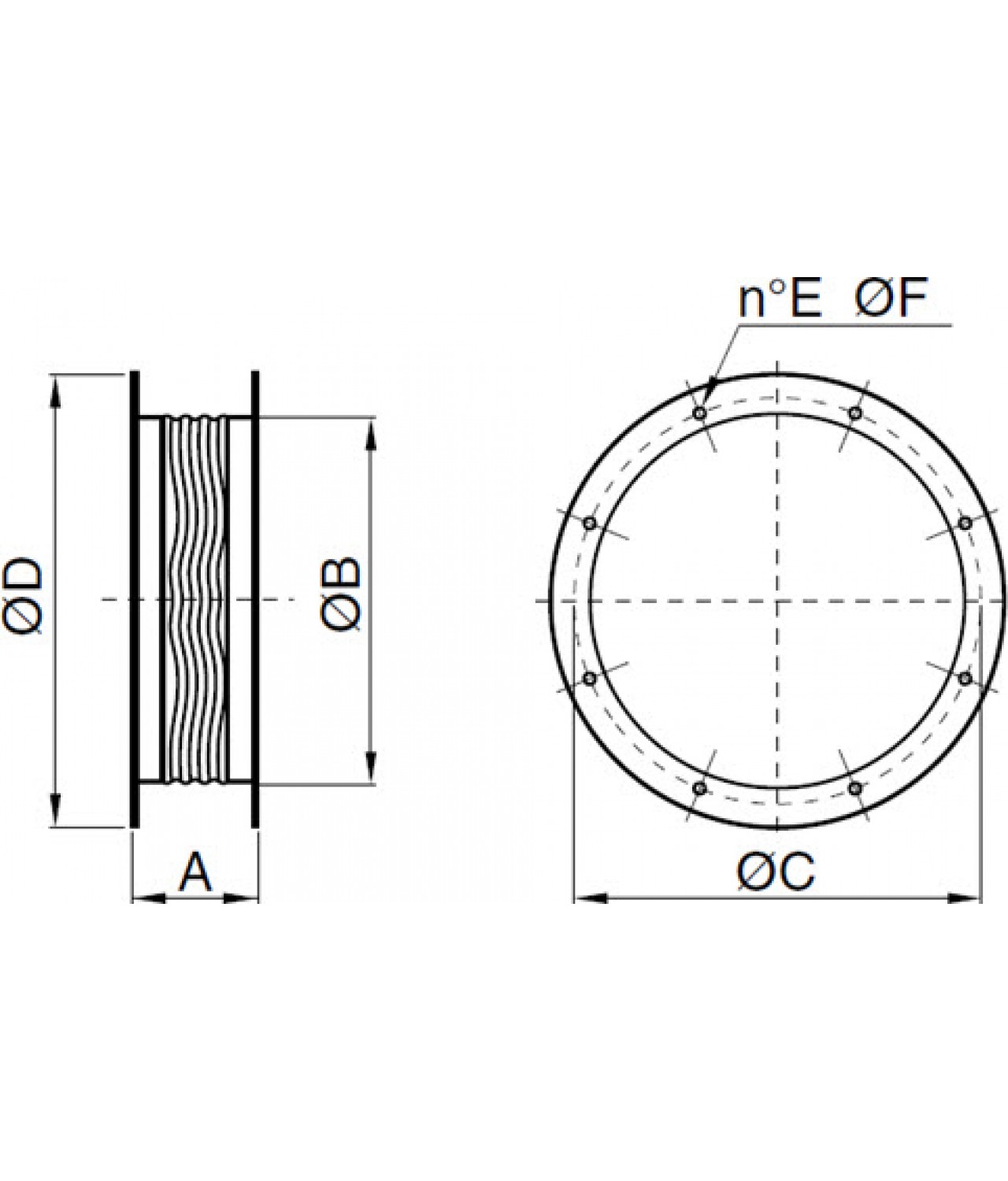

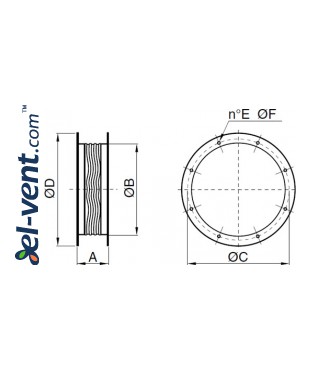

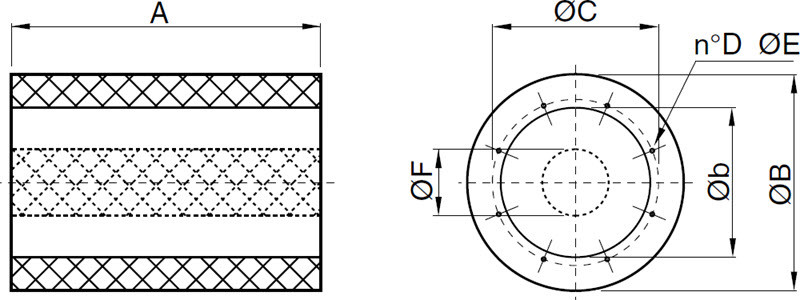

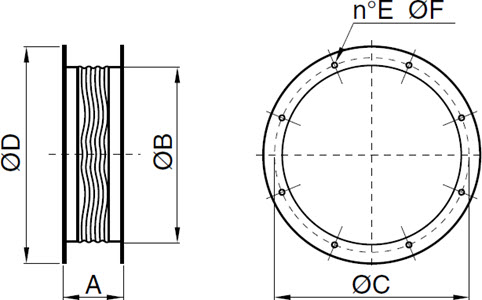

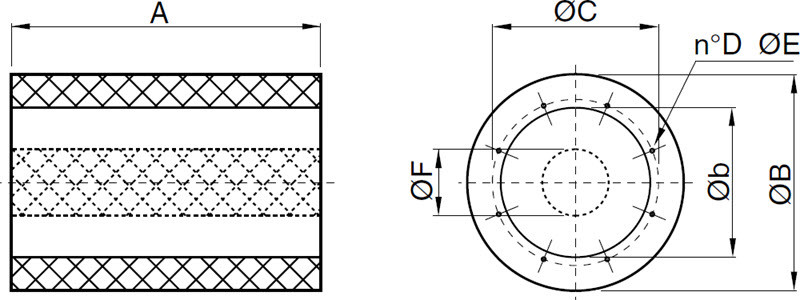

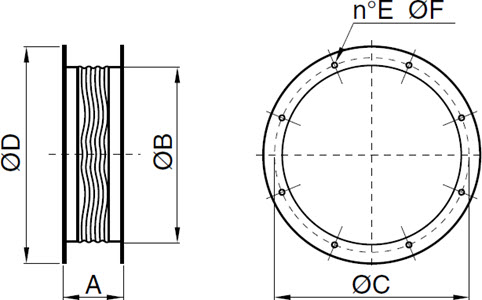

- CCga - flexible anti-vibration connector made with two UNI ISO6580 - EUROVENT compliant steel sheet flanges for attachment to the fan and duct and a robust flexible fabric connector. Operating temperature from -30 °C to +80 °C. The steel sheet components are protected against atmospheric agents by epoxy paint. Special versions available for different operating temperatures.

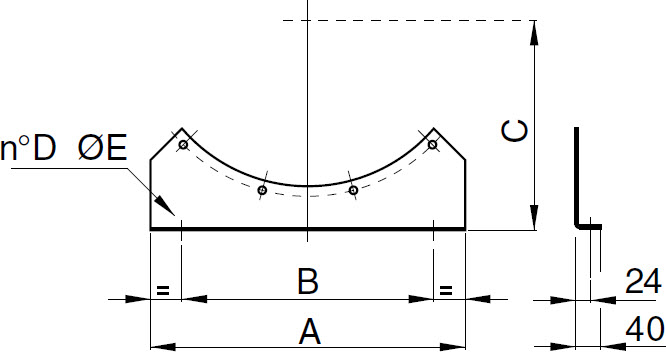

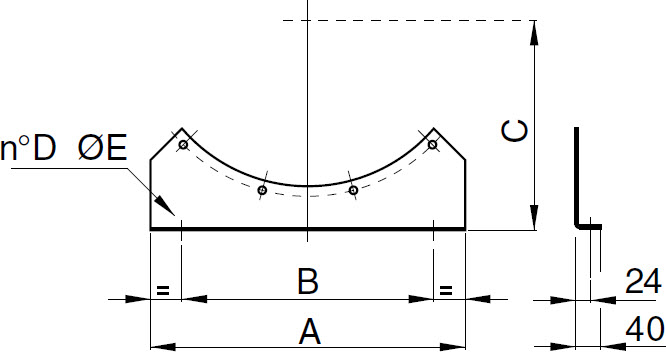

- CCst - support feet for mounting the fan on the floor or ceiling. Manufactured from sheet steel and protected against atmospheric agents by epoxy paint. 2 pieces of feet are included in the set when ordered.

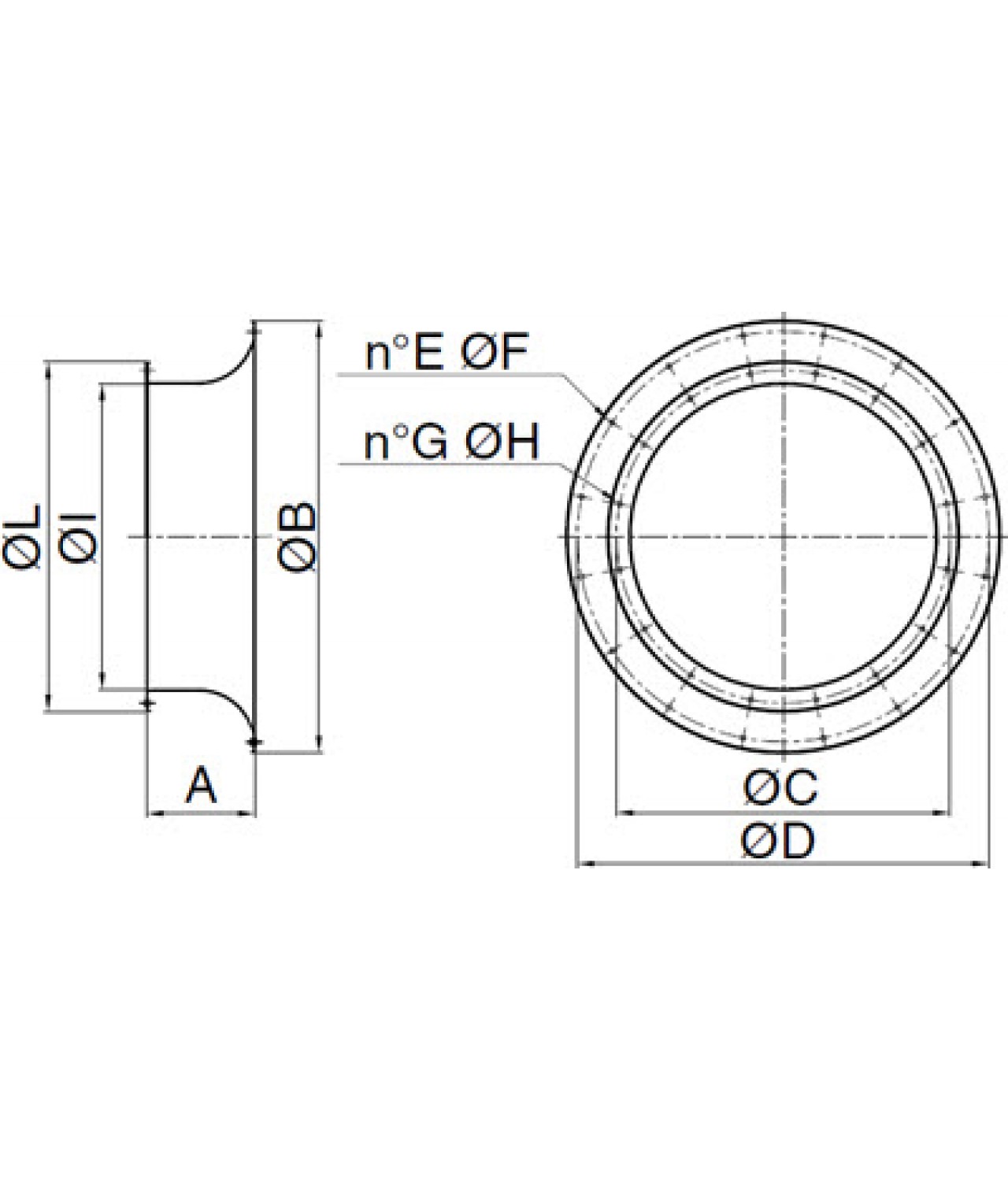

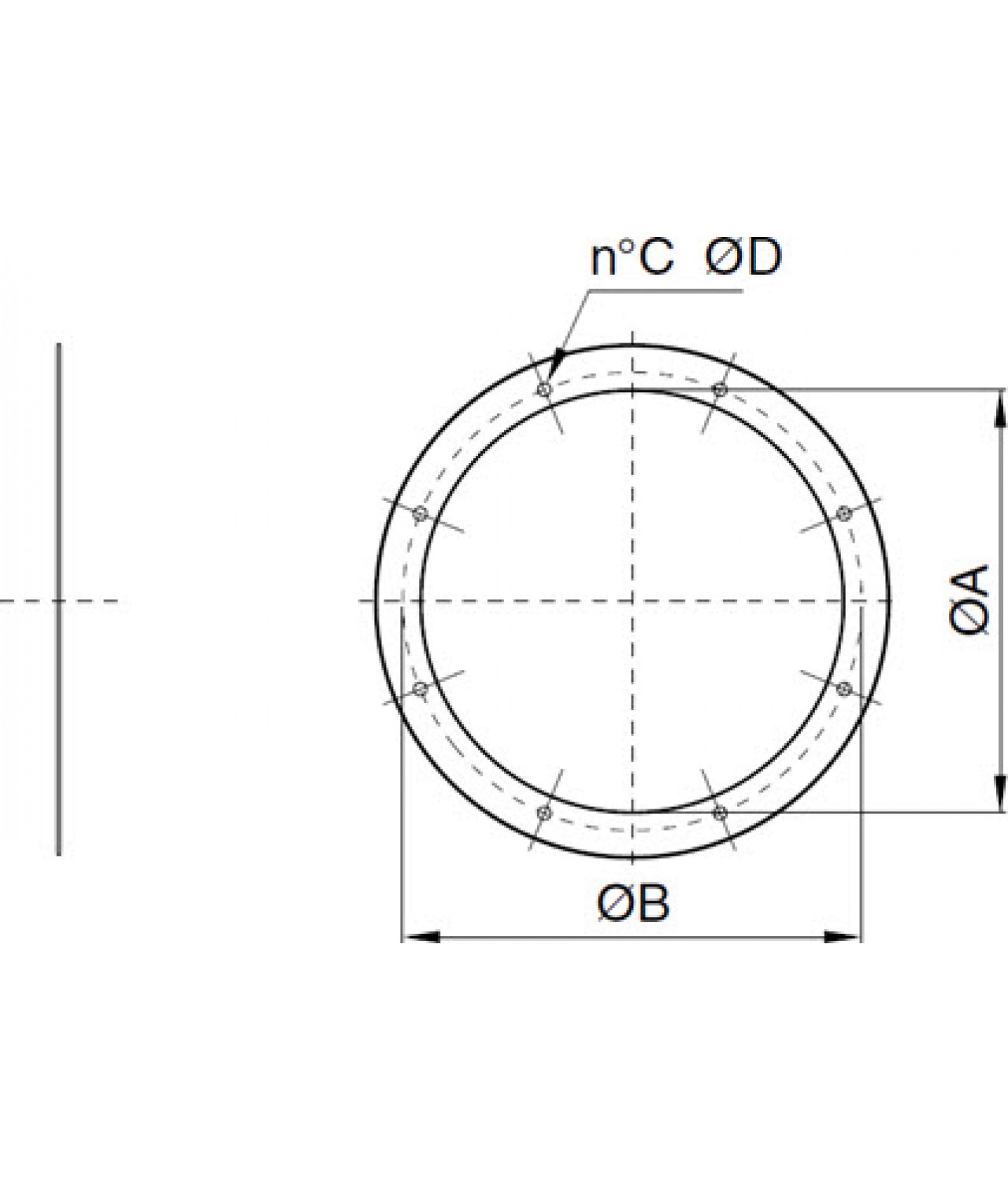

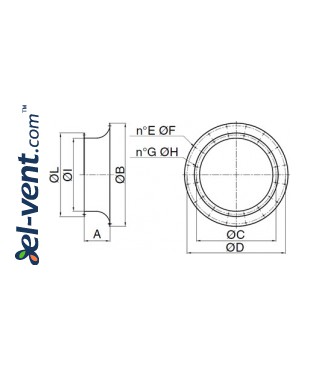

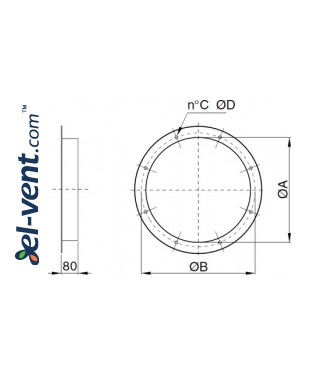

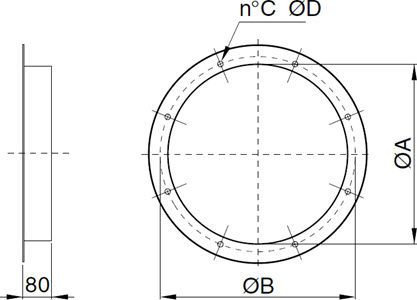

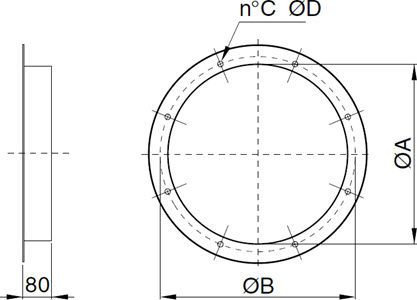

- CCf - connection ring to facilitate the connection of the duct to the fan, compliant with UNI ISO6580 - EUROVENT standard

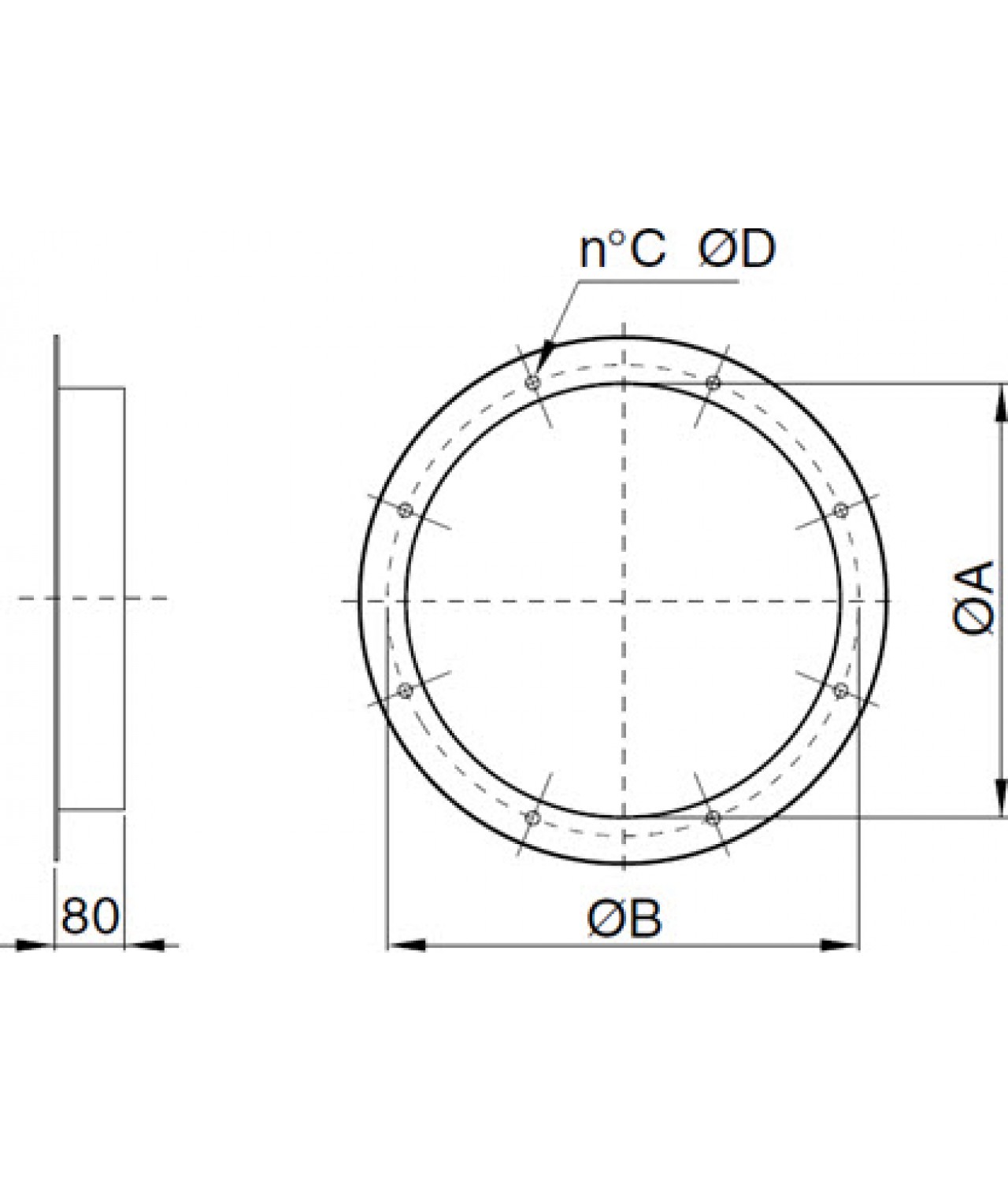

- CCfc - connecting ring with 80 mm grommet to facilitate the connection of the duct to the fan, conforms to UNI ISO6580 - EUROVENT standard

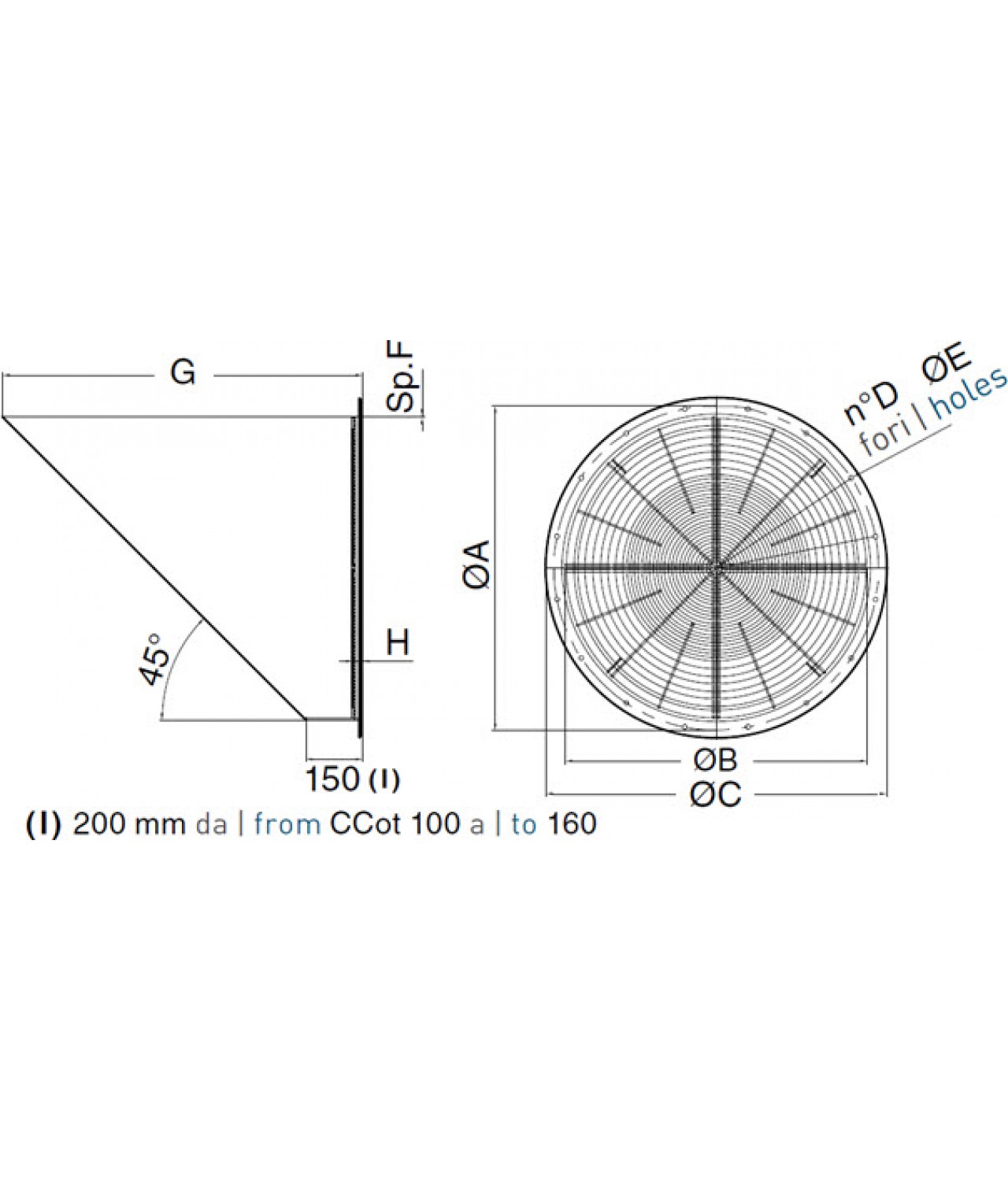

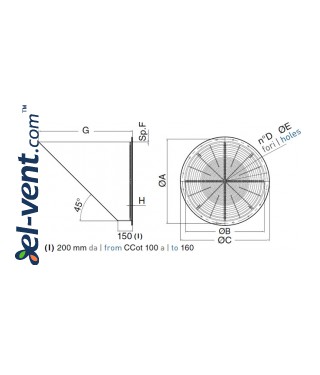

- CCot - air exhaust grille with protection against precipitation and birds or rodents

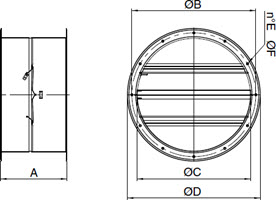

- BDD - backflow preventers help prevent heat loss when the fan is switched off. When the fan is running, the valve opens due to the air pressure caused by the fan. When the fan is switched off, it closes. The casing is made of painted steel sheet and the valves of galvanised steel sheet.

- speed controller, please choose fan model you wish to purchase and contact us to find the right one

- made in Italy

- 2 years warranty

Brand:

DYNAIR