- QCM ATEX H₂ - axial explosion-proof fans designed for operation in explosive atmospheres with presence of hydrogen

- manufactured and certified according to ATEX directive 2014/34/ES

- suitable for use in ATEX zone 1 II2G

- provide a high level of protection against explosions caused by hydrogen

- designed to convey clean air with temperatures from -20 °C to +60 °C, on request from -40 °C to +60 °C

CONSTRUCTION

- supporting frame made of drawn galvanized steel sheet with wide inlet radius

- impeller with airfoil blades in glass reinforced antistatic polyamide and aluminium alloy hub

- statically and dynamically balanced according to ISO 21940-11:2017

- execution 5 with direct coupling between motor and impeller

- airflow from motor to impeller

- motor side protection guard manufactured according to EN ISO 12499 and UNI 80079-37

ENGINE

- explosion-proof asynchronous three-phase or single-phase electric motor

- compliant with IEC 60034, IEC 60072, ATEX 2014/34/ES, EMC 2014/30/ES, LVD 2014/35/ES

- protection class IP55 according to EN ISO 20653

- insulation class F

- suitable for continuous duty S1

- overtemperature protection with PTC thermistors according to DIN 44081, DIN 44082 and IEC 60034-11-2

- speed control suitable by inverter for three-phase motors

- flameproof protection type db according to EN IEC 60079-0 and EN IEC 60079-1

ACCESSORIES (are not included in the ATEX type examination certificate)

-

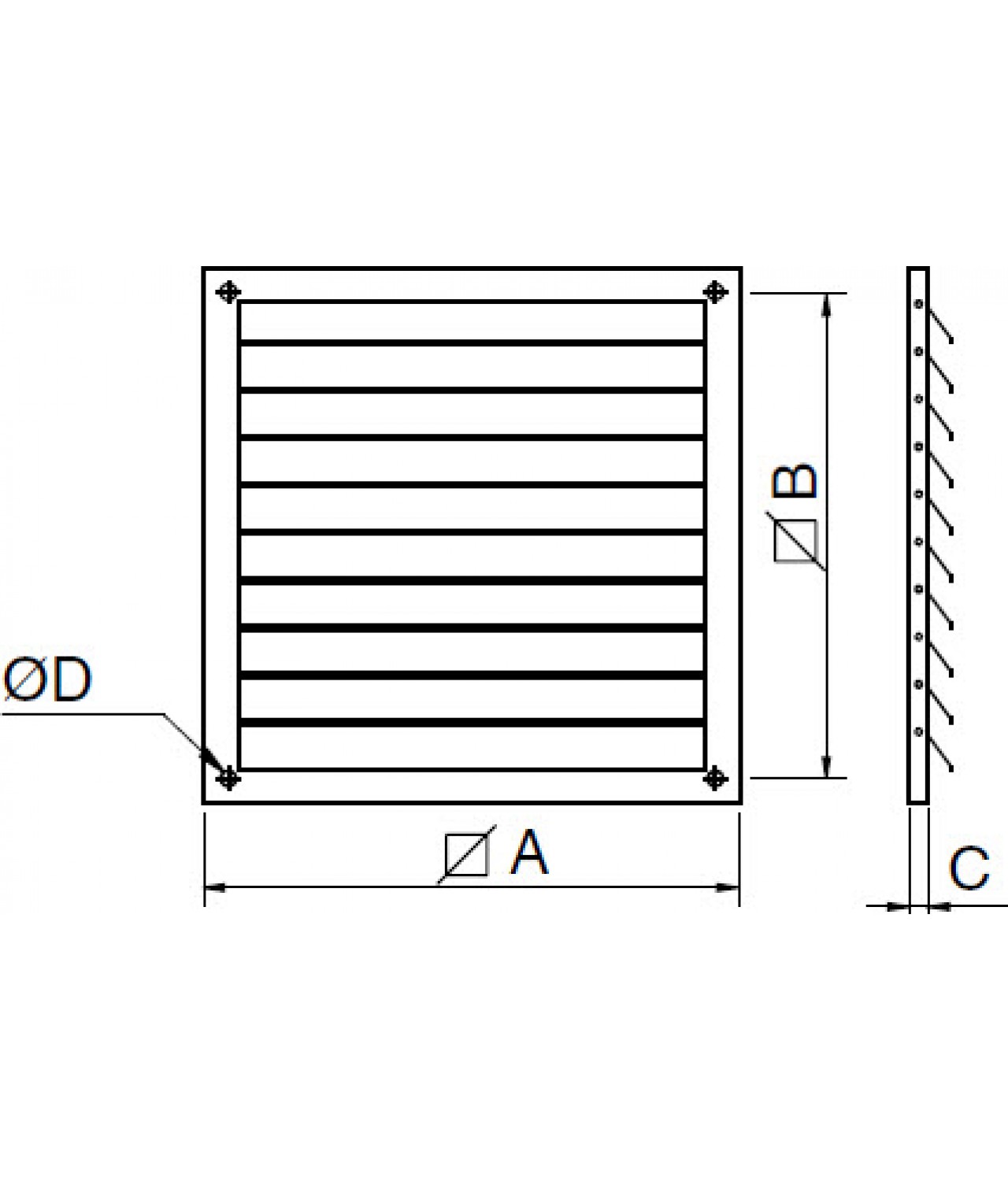

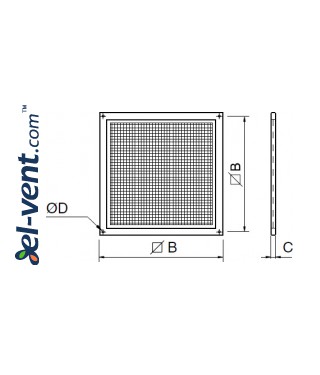

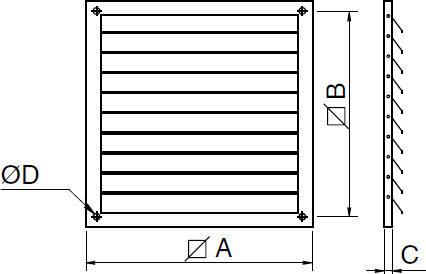

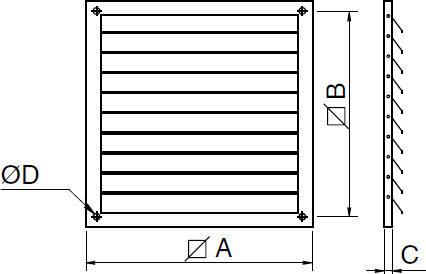

S - gravity grilles, mounted outside. This prevents heat loss, wind, rain and birds. When the fan is running, the airflow opens the edges of the louvre and when the fan is switched off, the louvre closes by itself. The frame is made of steel sheets with an epoxy powder coating and the edges are made of technopolymer. The use of gravity grilles results in a slight reduction in performance

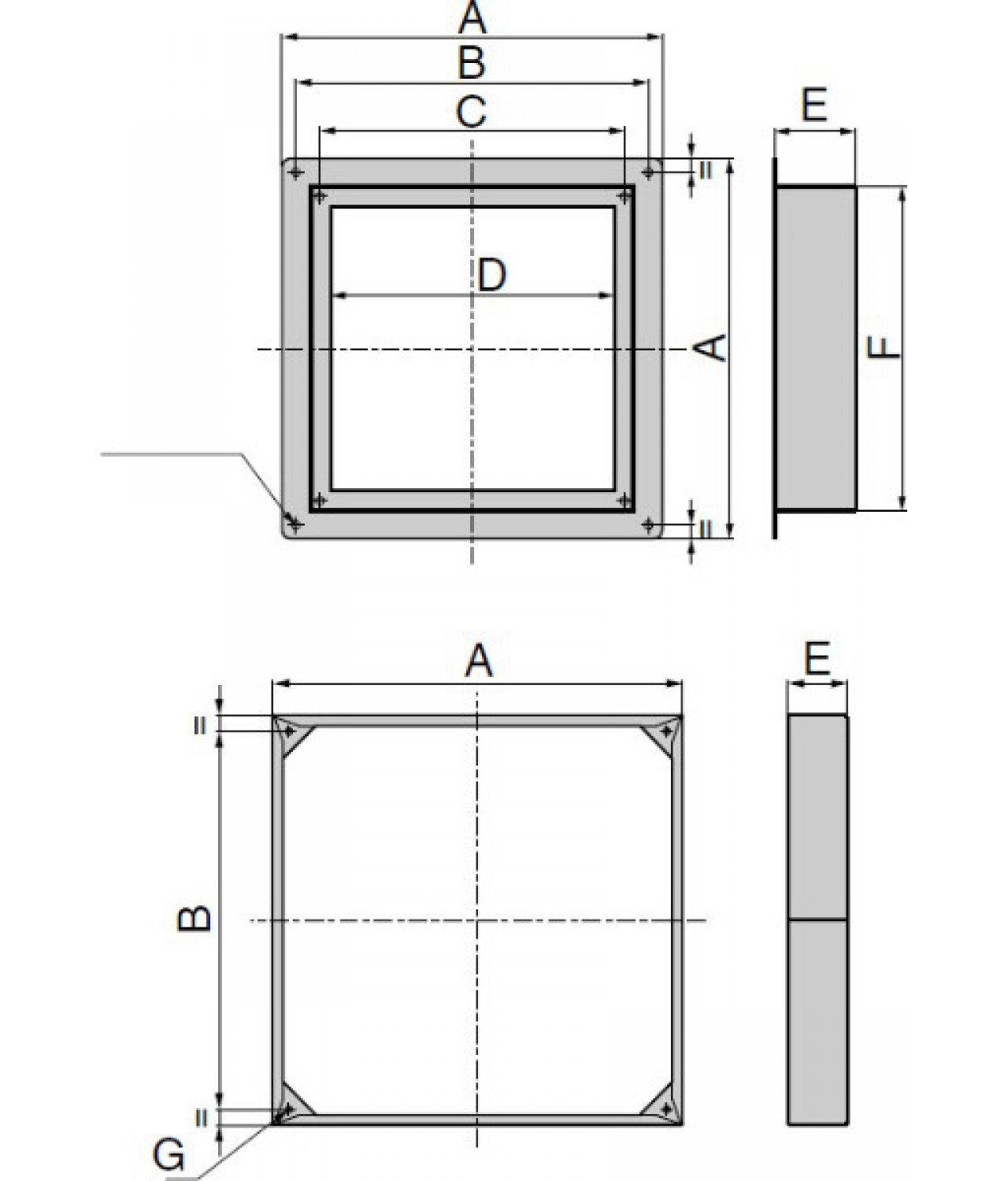

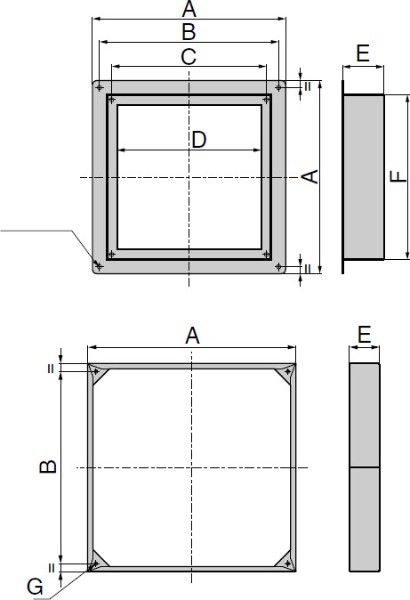

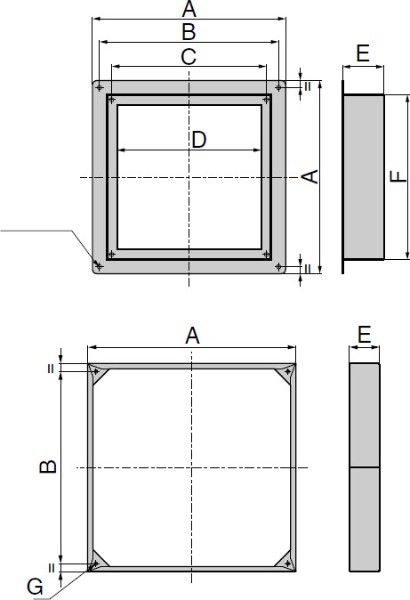

- D - adapter made of epoxy-painted steel sheet. It is required for the attachment of the fan when the width of the wall is less than dimension 'C' (the depth of the fan inlet). The frame shall be made of galvanised steel sheet (D63 and D71 epoxy powder-coated); the four corners shall be provided with 8 threaded inserts of galvanised steel sheet for the attachment of the fan on one side and of a gravity grille or protective mesh on the other

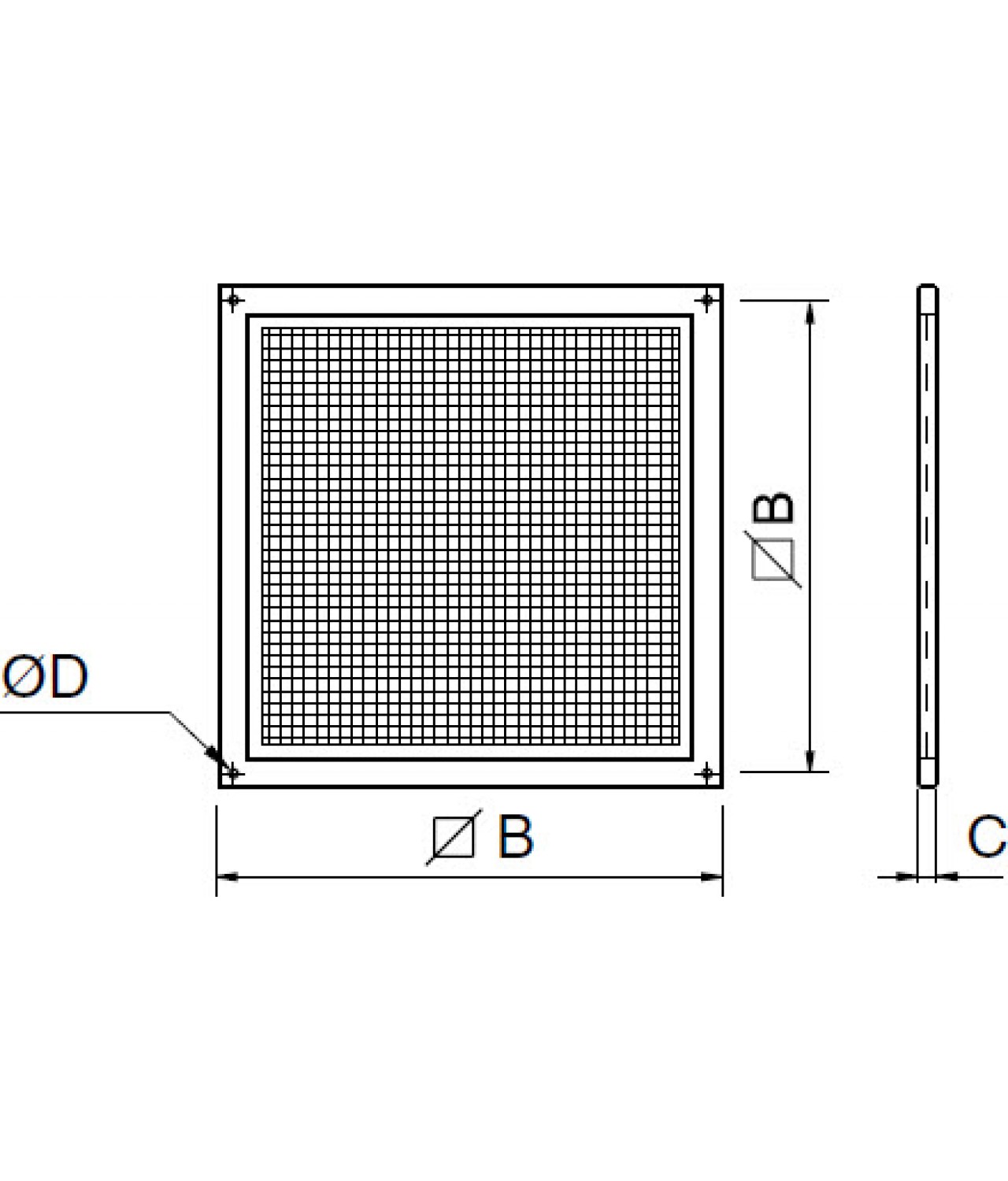

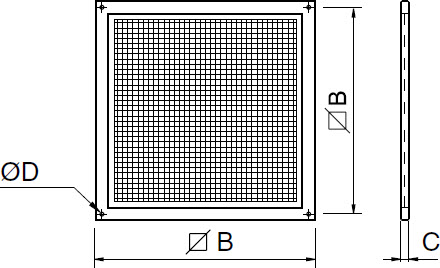

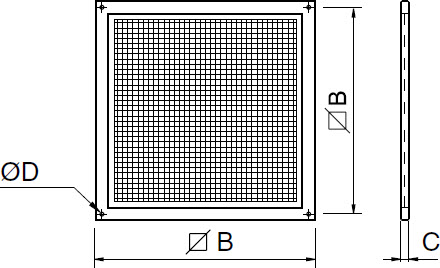

- R - impeller guard mesh, manufactured in accordance with UNI ISO 12499 and protected against atmospheric agents. This prevents accidental contact with the fan impeller. Frame and mesh made of epoxy-painted steel

- speed controller, please choose fan model you wish to purchase and contact us to find the right one

- made in Italy

- 2 years warranty

Brand:

DYNAIR